HOW WE BUILD

“Modular Manufacturing, Not Construction Under a Roof”

The future of the housing industry lies in standardization, not customization.

Some of the highest costs and biggest wastes in the construction industry come from customized design.

Standardized modular manufacturing creates efficiencies that help maximize materials, increase accuracy, improve assembly, and control costs.

Fading West offers a standard product line of single and multi-family homes.

We’ve applied LEAN principles used in the manufacturing industry for years to assemble homes in record time.

We build standardized modular homes with efficient processes in a controlled environment.

Which results in the following:

Standardization, Simplification, Process Flow

Experts, tools and tech that build modular homes with precision using high quality materials.

QUALITY

Faster build times in a single piece flow sequence, with

greater speed to market.

VELOCITY

Cost effective projects where developers build better homes and communities without breaking the bank.

COST

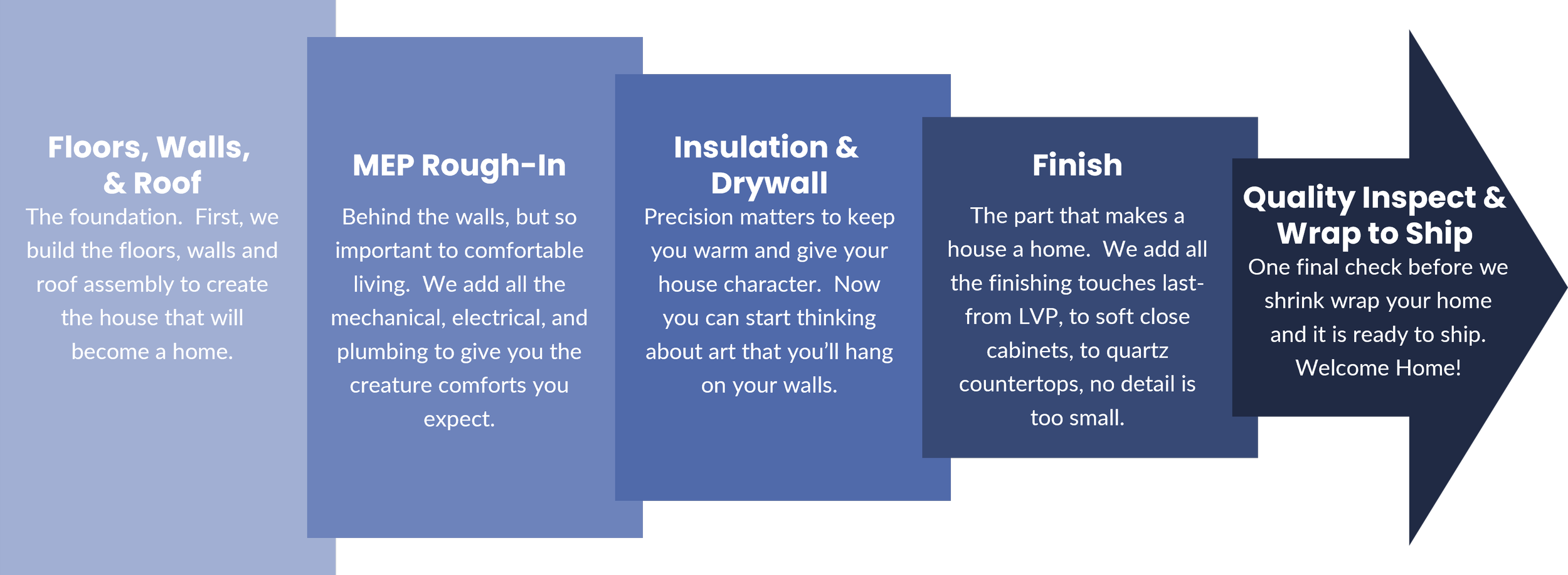

Building Process

Rather than building homes on-site, often made difficult by delays and limitations, our homes are assembled in our 110,000 sq. ft state-of-the-art Modular Home Factory in Buena Vista, Colorado using an assembly line manufacturing approach.

Throughout the modular manufacturing process, each building task is completed at a compartmentalized station and performed by specialized experts.

The manufacturing industry has been capitalizing on the efficiencies of standardized production for decades. Our mission is to revolutionize the housing industry with the same efficiencies and innovations made possible through LEAN thinking.

Our LEAN approach creates efficiencies at every phase of building - from the purchase of quality materials to the process of efficient installation.

LEAN practices have been applied across many industries, and the principles remain the same - lower costs, less waste, and faster results.

But LEAN culture is about more than the bottom line.

At the core of LEAN culture is a holistic approach to continuous improvement. For Fading West, it’s a promise to keep building better every day, in every way.